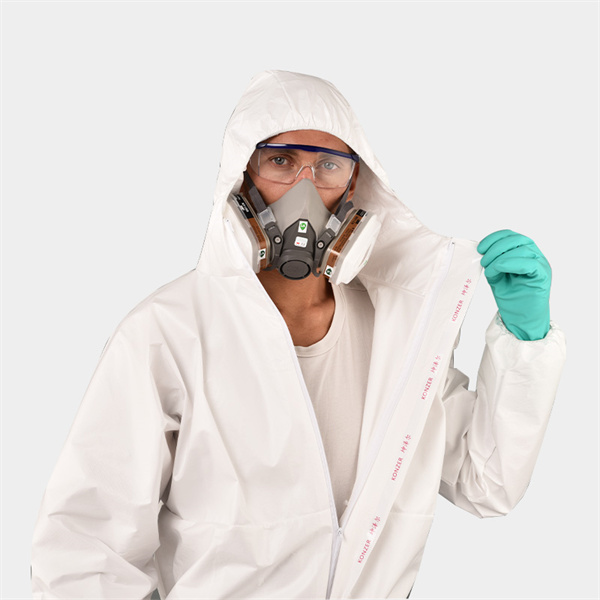

Medical protective clothing refers to protective clothing used by medical personnel (doctors, nurses, public health personnel, cleaning personnel, etc.) and individuals entering specific medical and health areas (such as patients, hospital visitors, personnel entering infected areas, etc.). Its function is to isolate bacteria, harmful ultrafine dust, acidic and alkaline solutions, electromagnetic radiation, etc., ensuring personnel safety and maintaining environmental cleanliness.

In addition to the specifications and safety requirements of the material itself, the performance of medical protective clothing mainly includes aspects such as protection, comfort, and physical and mechanical properties.

1. Protection

Protection is an important performance requirement for medical protective clothing, mainly including liquid barrier, microbial barrier, and barrier to particulate matter.

Liquid barrier refers to the ability of medical protective clothing to prevent the penetration of liquids such as water, blood, and alcohol, with a hydrophobicity level 4 or higher to prevent contamination of clothing and the human body. Avoid transmitting the virus carried by patients' blood, body fluids, and other secretions to medical personnel during the surgical process.

Microbial barrier includes the barrier against bacteria and viruses. The isolation of bacteria is mainly to prevent contact transmission (and reverse transmission) from medical staff to the patient's surgical wound during the surgical process. The blocking of viruses is mainly to prevent medical staff from coming into contact with patients' blood and body fluids, and the viruses carried by them can cause cross infection between doctors and patients.

Particle barrier refers to the prevention of viruses transmitted through the air from being inhaled or attached to the skin surface in the form of aerosols, which are absorbed by the human body.

2. Comfort

Comfort includes breathability, water vapor penetration, drapability, quality, surface thickness, electrostatic performance, color, reflectivity, odor, and skin sensitization. The main focus is on breathability and moisture permeability. In order to enhance the protective effect, the protective clothing fabric is usually laminated or laminated, resulting in thick, breathable, and poor moisture permeability. Long term wear is not conducive to sweating and heat dissipation. The anti-static requirement is to prevent static electricity in the operating room from causing the surgical uniform to adsorb a large amount of dust and bacteria, which is detrimental to the patient's wound. At the same time, it is to prevent sparks generated by static electricity from detonating volatile gases in the operating room and affecting the accuracy of precision instruments.

3. Physical and mechanical properties

The physical and mechanical properties mainly refer to the tear resistance, puncture resistance, and wear resistance of medical protective clothing materials. Avoid tearing and puncturing areas to provide a pathway for the spread of bacteria and viruses, and wear resistance can prevent flocs from falling and provide a place for the propagation of bacteria and viruses.

4. Other performance

In addition to the performance listed earlier, medical protective clothing should also have disinfection resistance, good color fastness to washing, anti shrinkage, non flammable, non-toxic and non irritating properties, and be harmless to the skin.